The Promise of Six Sigma – A rationale approach for process improvement in industry delivery

By Ian R. Lazarus, FACHE and Keith Butler, M.D.

(This article is presented in two parts. Part One introduces the concept of Six Sigma and its application in a variety of industry environments. Part Two follows certain projects through to conclusion while providing more advanced concepts to those considering the application of six sigma principles at their organization.)

“Statistical thinking will one day be as necessary for effective citizenship as the ability to read and write.” – H.G. Wells

How can you tell when an investment in quality improvement has truly paid off? Quality improvement consultants have suggested that “quality is like pornography…you know it when you see it.” But chief executives and senior managers clearly need more tangible measures for their investments in quality improvement and management effectiveness. Six Sigma, on the other hand, has done more than demonstrate improvements in quality; the techniques and philosophy of Six Sigma have fundamentally changed the way industry executives view their business. According to John Desmarais, CEO of Commonwealth Health Corporation (Bowling Green, KY), “it’s the single most important thing we have done in the history of our organization.” Indeed, when a quality improvement initiative has truly impacted the entire organization as it did at Commonwealth, the payoff is everywhere you look.

Six Sigma provides both the framework and tools to “get better faster,” a combination of statistical tools and project management techniques that enable managers to clearly define problems, measure and analyze them, and reach sustainable improvements in practice. Six Sigma recognizes that “variation is the enemy of best practices,” and it targets excessive variation and waste within the system to achieve its intended goal of reducing defects, improving profits, and delighting customers. It has been credited with saving literally billions of dollars among the manufacturing sector, including such heavyweights as General Electric, Motorola, Honeywell and Allied Signal.

That Six Sigma has a home in industry has already been amply demonstrated by pioneering CEOs like John Desmarais from Commonwealth and Joe Calvaruso at Mount Carmel Medical Center in Columbus OH (See Part One). The commitment of CEOs to the process also sends an important message to future proponents: Six Sigma will not work without a commitment from the top, and without it, there is no point in ever getting started. Senior management commitment to Six Sigma is critical because the process will invariably cut across department lines and change job functions. It will also require that the organization take its best people out of comfortable roles and into the front lines of new initiatives.

The popularity of Six Sigma in industry was clearly evident at the second annual Six Sigma Leadership Conference, held last October in Scottsdale AZ. Sponsored by the International Society of Six Sigma Professionals, the conference featured six presentations by health system executives, even though the event represented both manufacturing and service industries. “The industry industry, which has focused so much effort on the development of best practices, has a tremendous opportunity to gain from the application of Six Sigma principles,” notes Roxanne O’Brasky, President of ISSSP.

A new compass

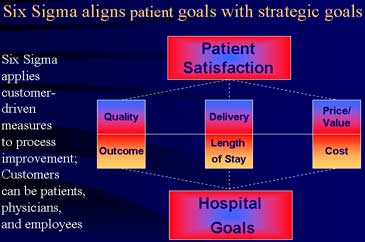

Most Six Sigma projects begin with a definition of industry deliverables that are critical to quality, delivery and price (see illustration). These tie inevitably to existing functions within the enterprise, and can be measured through the rate of defective procedures, length of stay, and cost. All too often, industry organizations find that their processes were designed around the convenience of their staff and physicians, and not the customer or patient. Ironically, physicians become strong proponents of Six Sigma programs once they understand the scientific basis and practical benefits of the methodologies.

It’s hard to ignore the potential and broad appeal of Six Sigma when talking to its proponents. Dr. Glenn Crotty, MD and COO of the Charleston Area Medical Center insists that “Six Sigma quality is more than a goal. It is a commitment woven deeply into the fabric of everything we do.” The changes caused through Six Sigma are “awesome and exciting” according to Lisa Thomerson, Six Sigma Corporate Champion at Commonwealth Health Corporation in South Central Kentucky. “Our CEO as well as our senior leaders are fully behind it. John Desmarais is full of passion. His commitment is tremendous.” To date, Commonwealth has invested about $900,000 and has realized improvements well in excess of $2.5 million.

Spare parts

There are multiple day-to-day applications of Six Sigma in the industry and managed care setting. Typical projects include billing office, supply chain management, emergency department, operating room, high volume DRGs and analysis of high cost admitters. Charleston Area Medical Center (CAMC), a 919-bed three campus medical center in Charleston, West Virginia, focused on supply chain management to test the potential of Six Sigma methodologies. Upon reviewing and identifying this project they found a $1.7 million opportunity within the inventory of surgical equipment that remained in storage for over a year. Over 50% of this inventory were in orthopedic trays. Further analysis revealed that old items were not being removed from shelves when new products replaced them. Once Six Sigma techniques were utilized to assess improvements from more rapid turnover of inventory, specific team members were assigned to negotiate with each principal vendor.

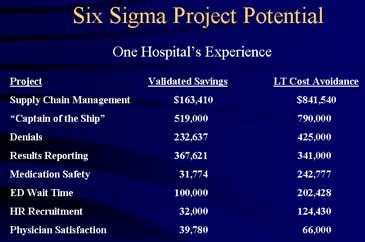

Requests for immediate refunds or “forward sales arrangements” were made that included no future requirement for bulk purchases. The medical center also initiated more rigorous inventory review procedures as part of Six Sigma’s “control process.“ Today, there are plans for a just-in-time inventory system with a centralized procurement database for all 3 hospitals. Although the initial savings in this project was merely $163,410 (from returned merchandise), future cost avoidance is estimated to be $841,540, according to Beverly Begovich, a fulltime Six Sigma Black Belt at CAMC. CAMC has moved forward on many additional Six Sigma projects, with stunning results (see illustration).

Out of control

In Six Sigma jargon, a process is said to be “in control” when it operates within acceptable specification limits. At Scottsdale industry (AZ), the process of “Bed Control” was decidedly “out of control.” The process of locating a bed and transferring a patient from the Emergency Department to the inpatient unit consumed fully 38% of the total time within the department (See Part One). Six Sigma consultants defined this problem as a “defect” and through additional analysis, found that the problem was not locating a bed, but reducing the number of steps required to make the transfer possible. The hospital employed the use of an Administrative Nurse to perform “inspections” by locating beds on different floors, and this process actually complicated the process rather than expediting it.

The process at Scottsdale industry violated two arguments of Six Sigma: that inspection is fundamentally unproductive, and the more interim steps you add to a process, the more you reduce the potential yield on that process. As a result of eliminating the Administrative Nurse position and through related streamlining techniques, the hospital reduced the cycle time for bed control by 10%, increased ED throughput by an estimated 0.1 patients per hour, and produced nearly $600,000 in incremental profit. The hospital system is now considering the application of Six Sigma in improving the performance of specific DRGs.

Culture Shock

Beyond obvious financial measures, the most significant change across these profiled institutions has been the development of performance improvement cultures. But what makes Six Sigma different from previous quality management programs? Ms. Thomerson from Commonwealth suggests “staff and involved physicians are buying it because it is data-driven, and is based on statistical analysis. It points to specific problems. Physicians understand and support this analytical approach to problem solving and improvements. They practice it everyday.” “Six Sigma gives practical applications to get projects started and to get them done quickly. People are tired of forever committees,” adds Ms. Begovich from CAMC.

Commonwealth Health Corporation’s, Six Sigma vision (posted plainly on their website) is that “by the year 2004, we will be proudly recognized by our employees, patients, clients, community, physicians and payors as the unquestioned leader in care and service, providing flawless quality never before achieved in the industry industry.” Their dependence on these techniques to deliver such impressive results is a testament to The Promise of Six Sigma.

“Shaken, not stirred”

If the culture of an organization can be described as a product of its “corporate DNA,” then Six Sigma aims to reshape the DNA of the organization, and to create a highly effective organism in the process. Its promise of “disruptive innovation” is cause for optimism and hope in an environment of regulatory and market constraints that are stifling in its effects. But CEOs considering Six Sigma must be careful not to push too hard or too fast. As with any cultural change, the process of introducing Six Sigma must be approached with patience and leadership.

Although the development of knowledge workers has been recognized as one of the most impactful competitive strategies available to service industries, implementing such a strategy in a industry enterprise can feel like trying to boil the ocean. Because change is uncomfortable, CEOs can expect initial resistance and anxiety in connection with these efforts. If not addressed early on, any of the following conditions can ultimately lead to a failed attempt at implementing Six Sigma methodologies:

- Lack of understanding of Six Sigma principles

- Ambivalent involvement of senior management

- Lack of broad participation and involvement

- Dependence on consensus-based decisions

- Initiatives too broad or too narrow in scope

- Failure to attack cultural impediments

Ultimately, the CEOs job in implementing Six Sigma is to engineer a cultural change first that recognizes the moral imperative of the organization to forge new ground in performance improvement. Attitudes that suggest “we are the best we can be” must be replaced with “we must get even better.” Constant monitoring to ensure quality must be replaced by systems and controls that make defects nearly impossible. On one hand, it may seem that Six Sigma demands as much from the organization as it delivers in return. This may be a valid observation, but you do not hear any of its proponents expressing anything but enthusiasm and anticipation from the promise that Six Sigma can offer them.

Ian R. Lazarus, FACHE and Beatriz Stamps, MD MBA are principals with Creato Performance Solutions (www.creato.com) a consulting firm providing strategic advisory services, including Six Sigma consulting, to industry providers and suppliers.